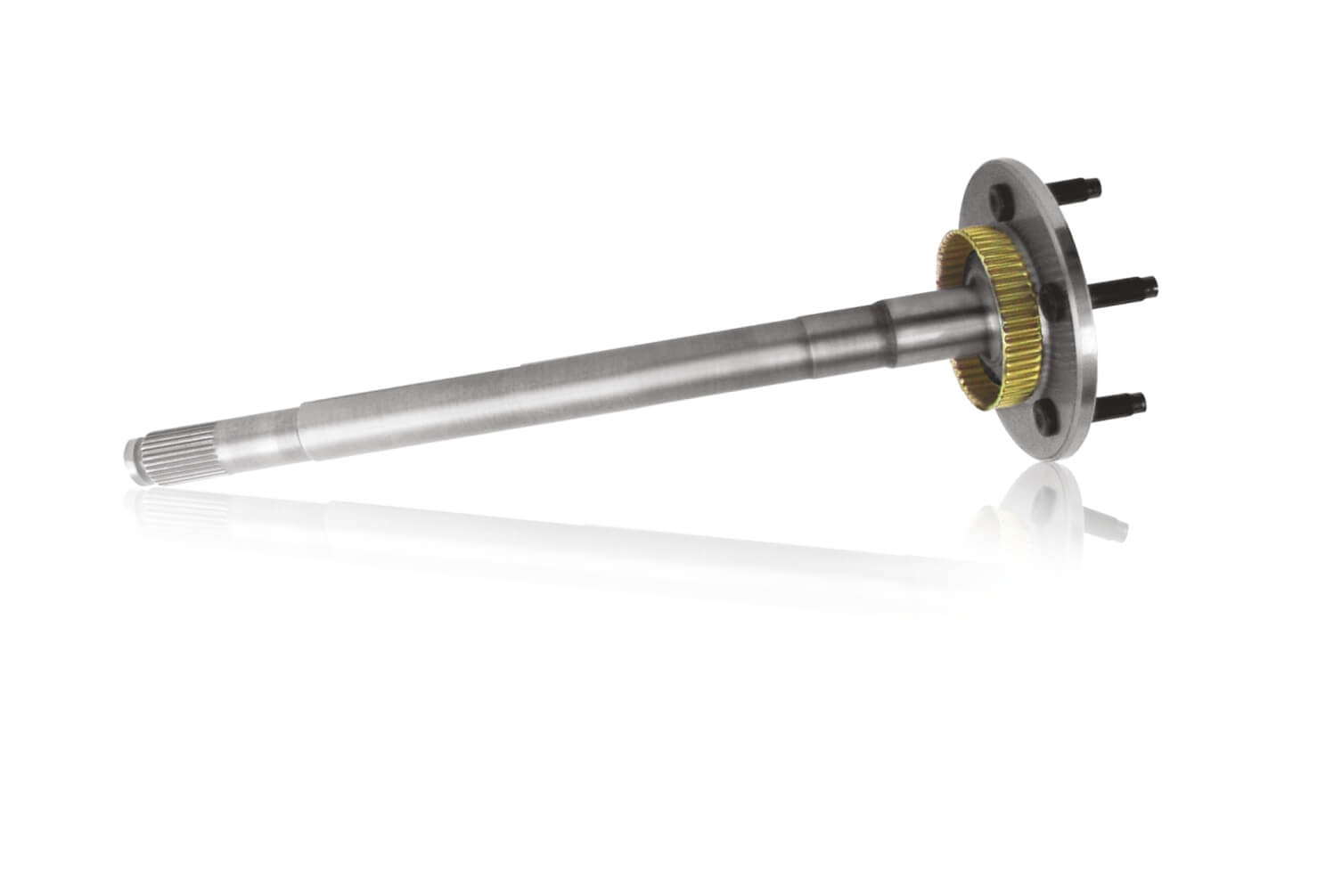

Rear Axle Shafts

We have been manufacturing Rear Axle Shafts ever since 1993. Availability of extensive tooling, completely integrated manufacturing facility with state-of-the-art machines and product expertise through dedicated manpower backed by three decades of experience and strong management allows us to produce the samples of the customers first time right and reduce the manufacturing lead time.

| Capacity | 600,000 Nos. Annual. Axle Shafts with Flange Dia from 30mm to 255mm, Shaft Diameter from 20mm to 80mm and length up to 1200 mm |

| Machinery | Upset Forging, Heat Treatment, CNC Machining, CNC Grinding, CNC Induction Hardening, etc. |

| Materials | AISI 1541, EN8D, EN15B, EN18, 40Cr, AISI 4140, EN19, 42CrMo4, AISI 4340, EN24, etc. |

| Supply Conditions | Fully Machined, Shot Blasted, Turned, Ground, Peeled, Gun Drilled, Blanks, Cut to Fit Splines, Multiple Bolt Patterns, Fully Assembled with Axle Studs, ABS Ring, Oil Seal, Retainers Bearing etc. |

| Industries | Light-Duty Automotive, Medium Duty Automotive, Heavy Duty Automotive, Agricultural Tractors, Off-Highway Construction Vehicles, Off-Road Racing, Oval Track Racing, Drag Racing and Demolition Derby Racing |

| Product Types | Full Float Axle ShaftsSemi Float Axle ShaftsDouble Spline Axle ShaftsHalf Axle ShaftsAxle Stubs |

More in Category

Manufacturer of High-Quality Automotive Components

Reliable, Precise & Performance Driven

Automotive Components & Services!

EMMFORCE has been built on engineering excellence crafted through unstinted dedication to quality, innovation and a constant objective to serve the global automotive market & 2+ decades young industry expertise.

Customer Centric Best Quality

Stringent quality checks at each step through - CNC Coordinate Measuring Machines, CNC Gear Analyzer, Video Vision, Microscopes with Image Analyzer, Micro Hardness Testers, Vickers, Rockwell and Brinell Hardness Testers, Industrial Component Washing Machines, Millipore Test Apparatus, End of Line Testing Machines, Product Life Cycle Testing Machines, etc.

Fully Integrated Manufacturing Setup

In-house R&D, Forging, Full CNC Induction Hardening, Heat Treatment, Full CNC Machine Shop with facilities like Turning, Hobbing, Shaping, Shaving, Broaching, External & Internal Grinding, HMCs & VMCs, Assembly, Material Testing & Packaging.

The Force Behind EMMFORCE

Highly skilled workforce of 150+ engineers and machinists, who are passionate to deliver first time right product that exceeds customer’s expectations on quality, timely delivery and cost.